Making a Tesla coil secondary

This is my first Tesla coil secondary. It will be wound semi-manually to get a sense of the process before attempting to automate future builds.

Design: 80mm diameter PVC pipe, 26 AWG enameled wire, 320mm height (4:1 aspect ratio).

Estimated wire needed: ~201m (based on 800 turns × π × 0.08m circumference)

I also made this calculator to assist with design:

https://harrisfauntleroy.github.io/tesla-coil-secondary-calculator

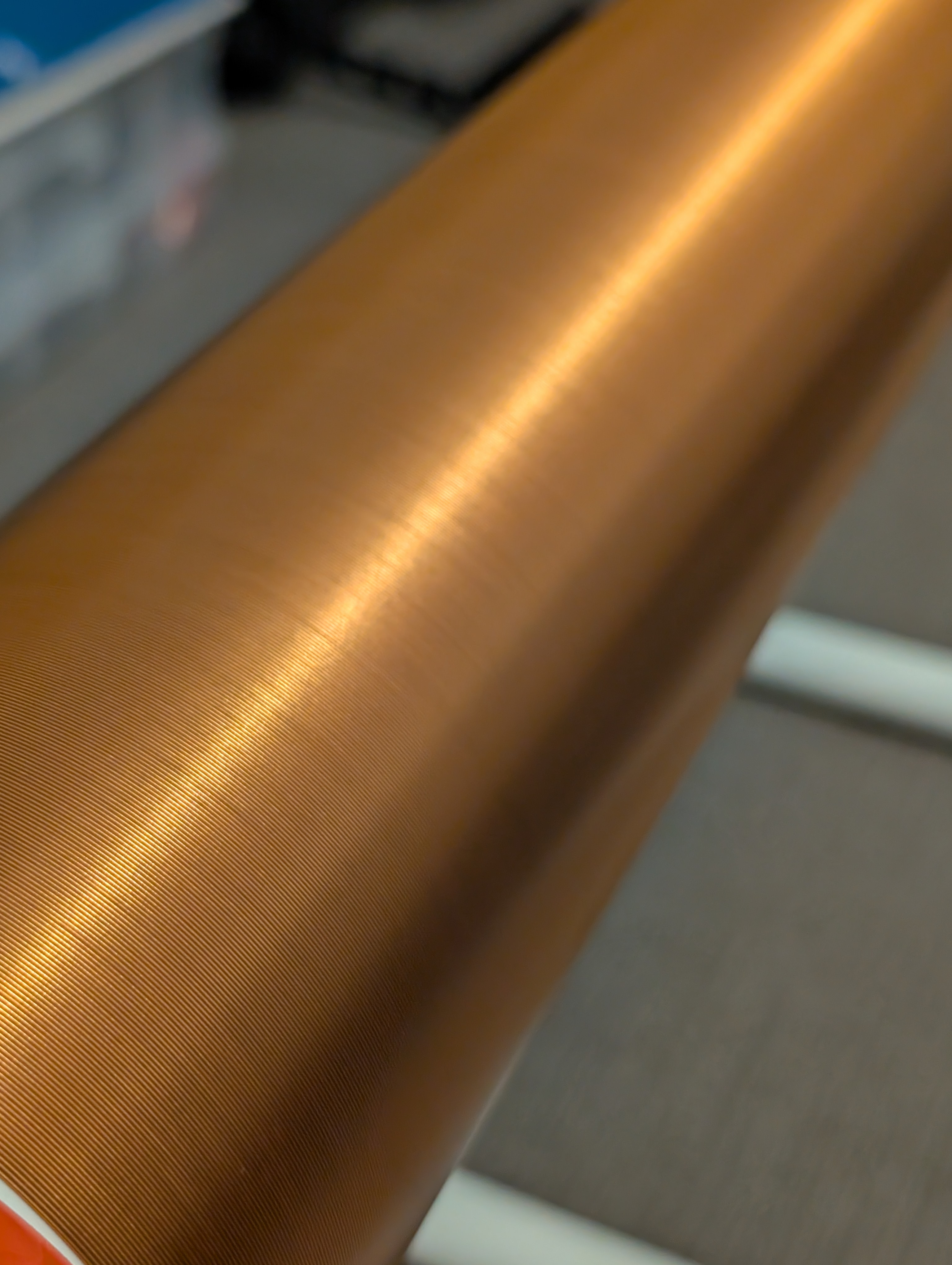

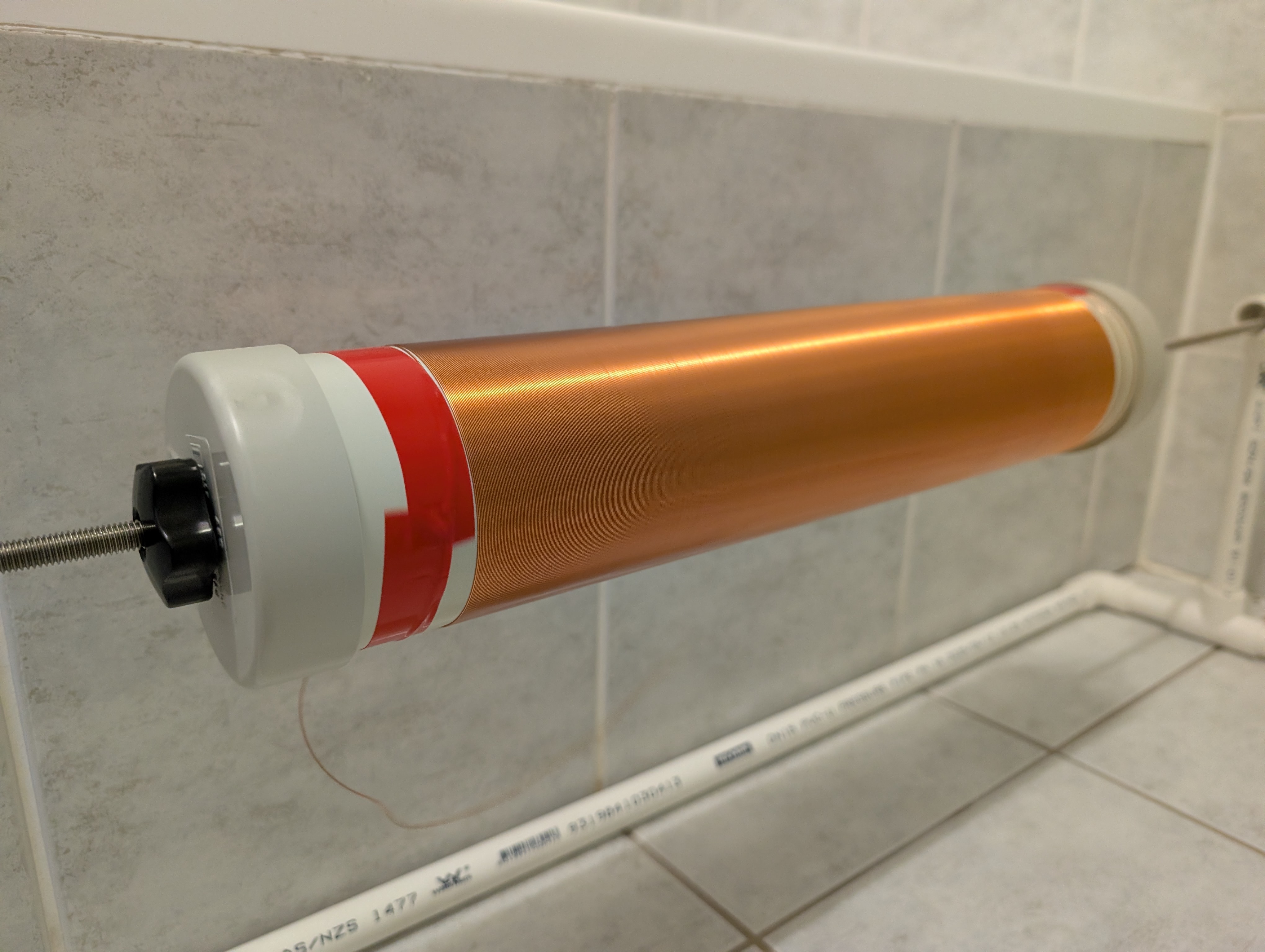

Close ups of the coil

Design Parameters:

| Parameter |

Value |

| Coil form diameter (D) |

80mm (0.08m) |

| Wire gauge |

26 AWG |

| Wire diameter (d) |

~0.45mm (measured) |

| Target winding height |

320mm |

| Aspect ratio |

4:1 |

Measured Properties:

| Property |

Measured/Actual |

| DC Resistance |

28Ω |

| Turns |

823 (calculated) |

| Wire Length |

207m (calculated) |

| Inductance (L) |

? |

| Capacitance (C) |

? |

Process with images

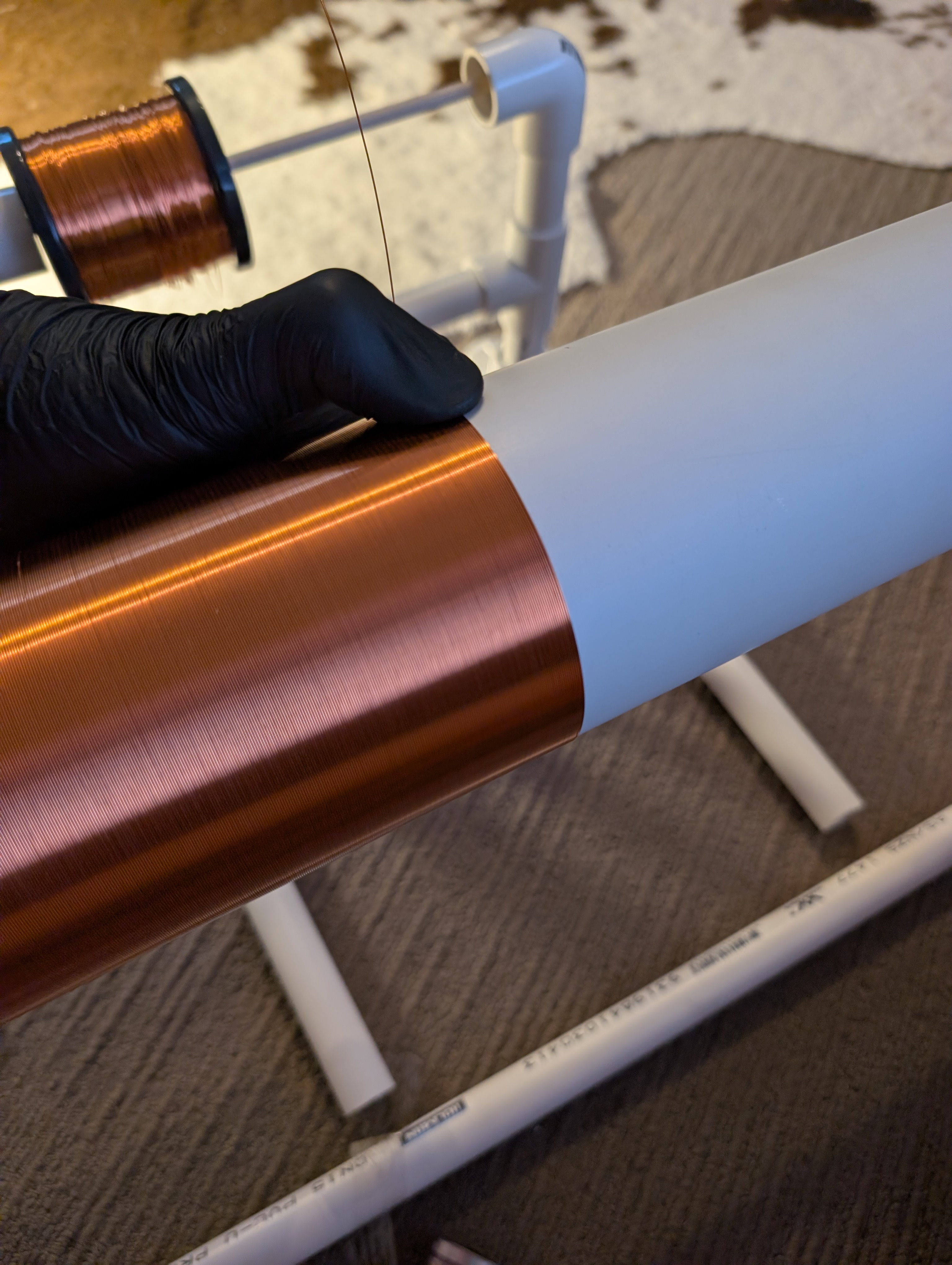

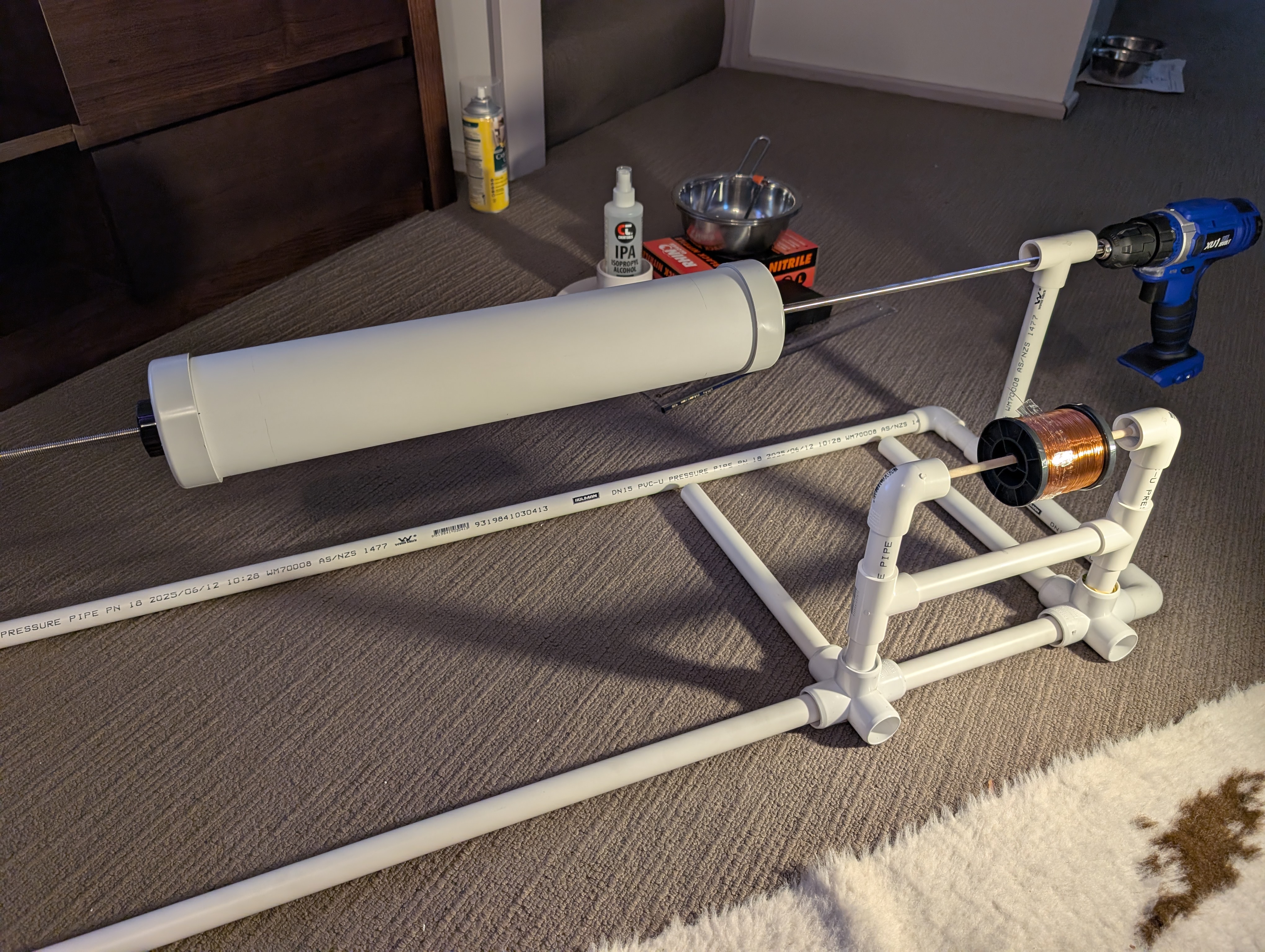

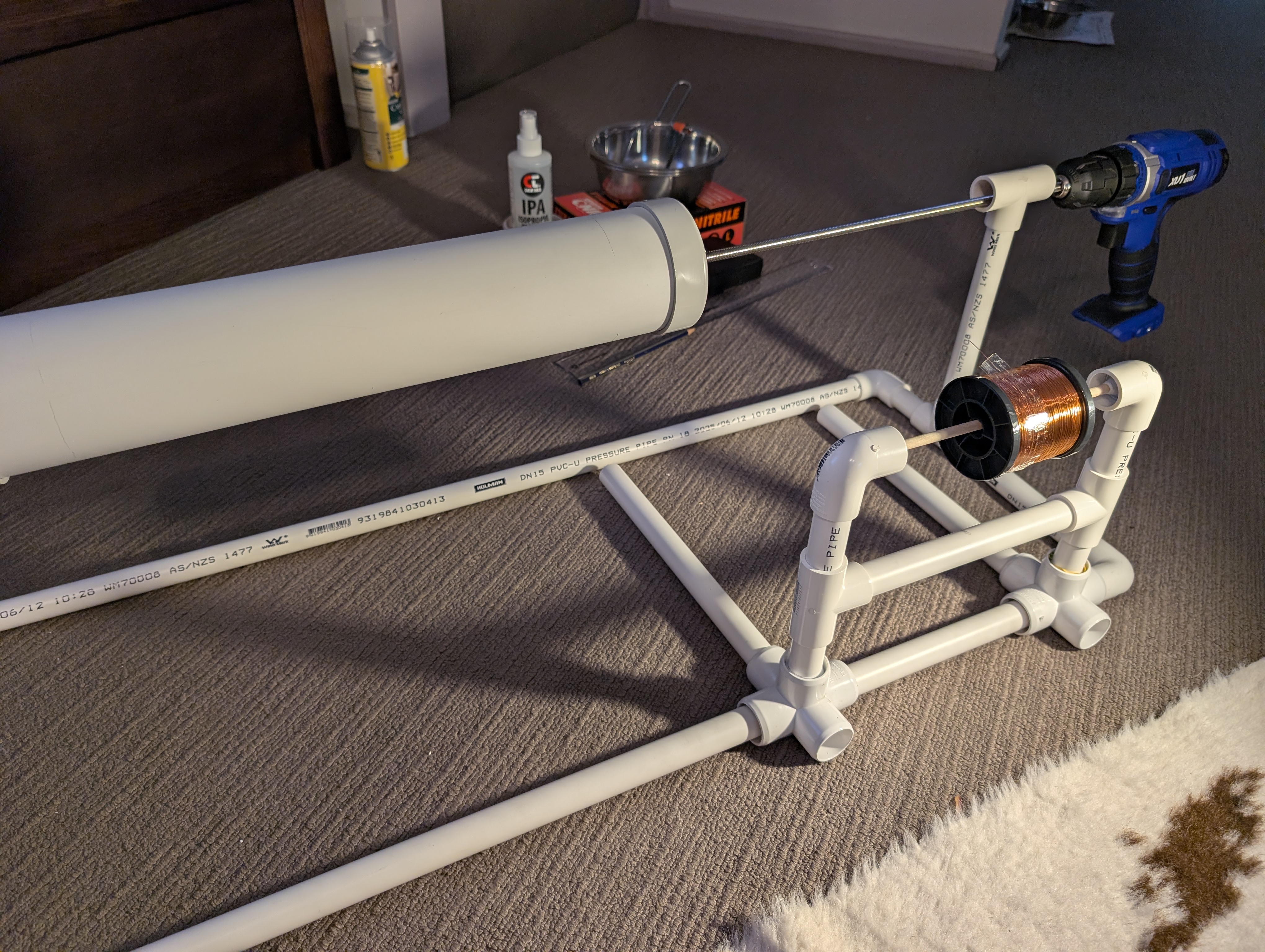

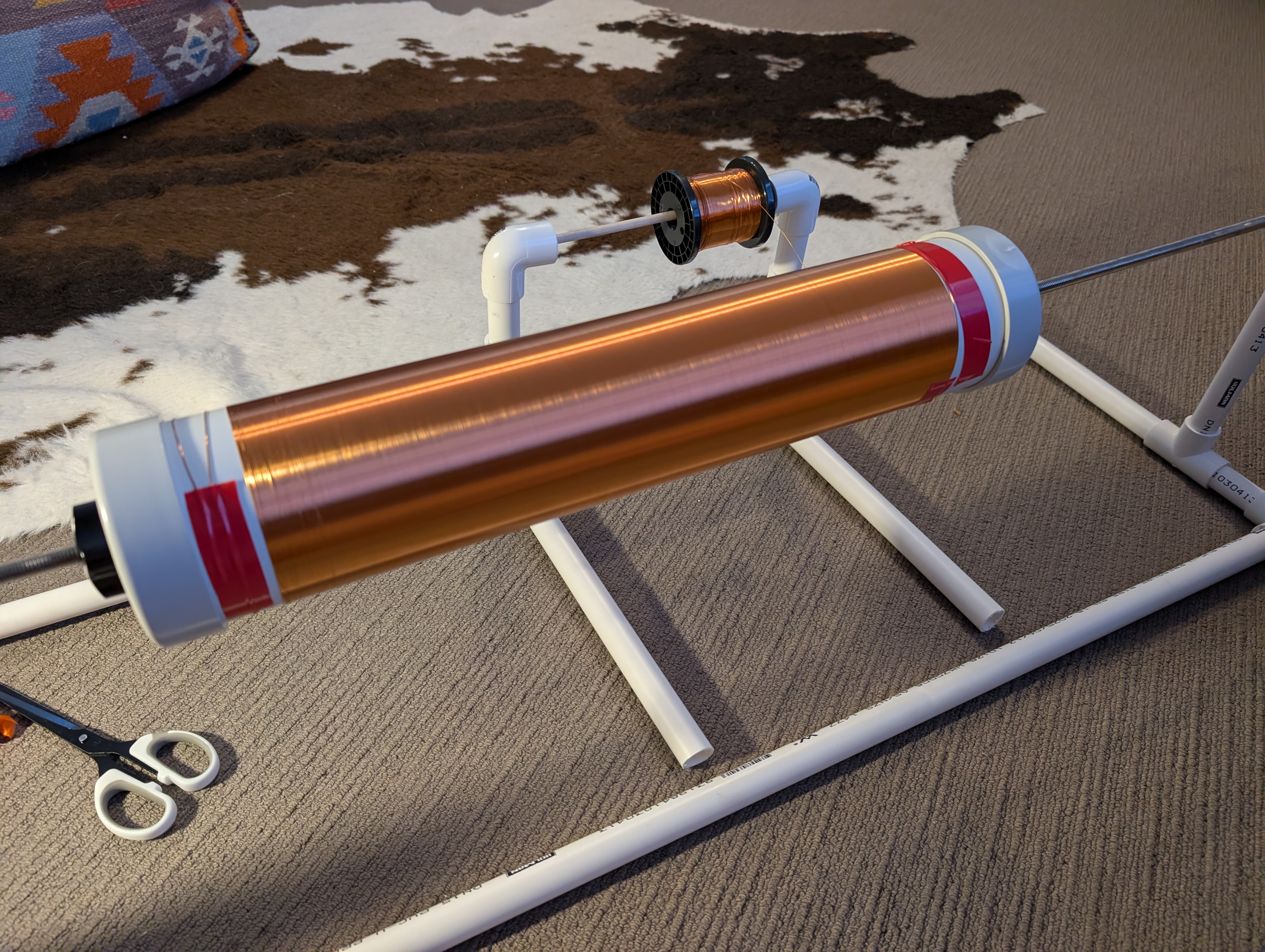

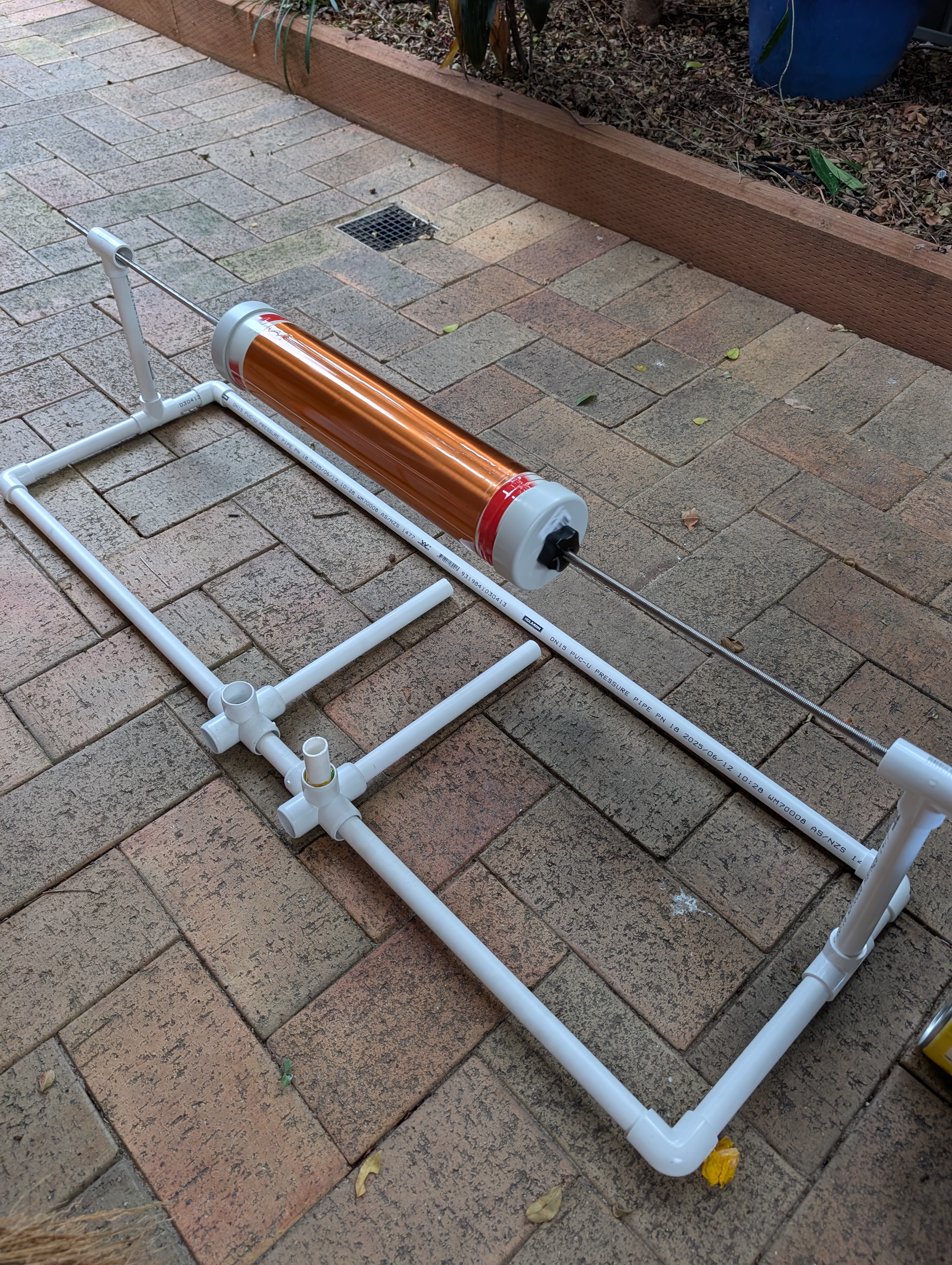

Preparing the coil form and rig. Used a variety of 15mm PVC pipe pieces to make the rig.

Winding the coil, used a hand drill to turn the coil form while hand guiding the wire, keeping layers close by guiding it with a piece of plastic.

Applying spray on polyurethane lacquer. Will likely do multiple coats.

Sources / Inspiration

The first gulp from the glass of natural sciences will make you an atheist, but at the bottom of the glass God is waiting for you. - Werner Heisenberg

Forums

Forums

Making a Tesla coil secondary

Making a Tesla coil secondary

04 Oct 2025 at 11:46 PM

04 Oct 2025 at 11:46 PM

Legal information

Legal information

Joined: Thu Jun 12 2025, 05:17AM

Location: Prague

Posts: 31

Test

The first gulp from the glass of natural sciences will make you an atheist, but at the bottom of the glass God is waiting for you. - Werner Heisenberg